Category:Manufacturing

Introductory Citations | |

|

- Factory@Home report [1] |

- Jason F. McLennan [2] |

Overview | |

IntroductionPlease read:

This new section is dedicated to Open Manufacturing developments, making it easier to identify interests in creating physical objects. This is a smaller subset of our much broader section on Open and Shared Design Communities. However, this section also includes developments about 'production' and 'making' in general, including topics like the DIY revolution, the digitalization of crafts, and agricultural production. The P2P Foundation supports the aims of the Open Source Hardware and Design Alliance [3] , an initiative to foster sustainable sharing of open hardware and design. Have a look at the following material:

Video: Four Ways to Manufacture Open Hardware. How does open hardware get made? 1) Licensing; 2) Fulfillment; 3) Contract manufacturing; 4) DIY assembly [4] Comparative Tables

|

The Personal Manufacturing IndustryFor details see: Personal Manufacturing Industry and Personal Manufacturing Machines Introduction: an overview of Personal Manufacturing Read:

ToolsSee: Personal Manufacturing Tools Typology of Personal Manufacturing Machines (Hardware)

Computer-Aided Design Software

Players

|

Visualization

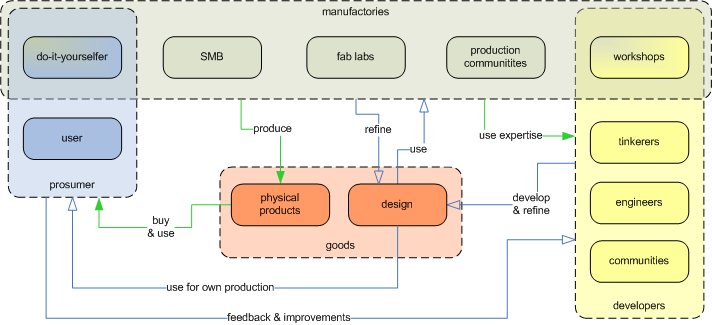

Reto Stauss: The Open Manufacturing Value Stream

Contacts

|

|

|

|

|

| |

| Bryan Bishop | Kirsty Boyle | Charles Collis | Vinay Gupta | Eric Hunting | Marcin Jakubowski | |

| kanzure AT gmail DOT com | kirsty AT openmaterials DOT org | charles dot collis at gmail dot com | hexayurt AT gmail DOT com | erichunting AT gmail DOT com | joseph dot dolittle at gmail dot com | |

|

|

|

|

|

||

| Smári McCarthy | Massimo Menichinelli | Catarina Mota | Sam Rose | Chris Watkins | ||

| spm2 AT hi DOT is | info AT openp2pdesign DOT org | catarina AT openmaterials DOT org | samue.rose AT gmail DOT com | chriswaterguy AT appropedia.org |

Key people in the Open Hardware movement

- Peter Semmelhack ; founder and CEO of Bug Labs

- Nathan Seidel ; CEO of SparkFun Inc. in Boulder, Colorado

- Matt Peddicord ; Matt Peddicord is Director of Operations at Bug Labs, Inc.

- Dave Mellis ; lead software developer for Arduino

- Bunnie Huang ; hardware lead at chumby Industries

- Limor Fried ; founder of Adafruit Industries

- Dale Dougherty ; founder of Make magazine and the creator of Maker Faire

- Xavier Carcelle ; CTO for OpenPattern

- Jim Barkley ; Open Services, at The MITRE Corporation

- Massimo Banzi ; Massimo Banzi is the co-founder of the Arduino project

CitationsSee also our Citations on Open and Shared Design and Open and Distributed Manufacturing | |

improvements in fabrication technologies will be a pivotal development in the 21st century. – Simon Bradshaw, Adrian Bowyer and Patrick Haufe [5]

- Jason F. McLennan [6]

The Inevitability of Personal Manufacturing as new Industrial RevolutionAccording to Marshall Burns, previous emancipating technologies in human history were the book (enabled by the invention of the printing press), cars (enabled by new roads and gas stations) and now personal fabrication (enabled by 3D design software). What this random collection of technologies has in common is that they entered the lives of everyday people in a gradual way as the technology dropped in price, became easy to use, and accumulated a critical mass of applications, fellow users, or supportive infrastructure such as roads or high speed Internet. While mainstream adoption of personal manufacturing technologies is a few decades away, the manufacturing industry will experience the same forces that brought us YouTube, laptops, mobile phones and online retailers." - by Hod Lipson & Melba Kurman [7]

Why Localization is Inevitable in a Resource-scarce World"It is an article of faith that global trade will be an ever-growing presence in the world. Yet this belief rests on shaky foundations. Global trade depends on cheap, long-distance freight transportation. Freight costs will rise with climate change, the end of cheap oil, and policies to mitigate these two challenges. At first, the increase in freight costs will be bad news for developed and developing nations alike but, as adjustments in the patterns of trade occur, the result is likely to be decreased outsourcing with more manufacturing and food production jobs in North America and the European Union. The pattern of trade will change as increasing transportation costs outweigh traditional sources of comparative advantage, such as lower wages. The new geography of trade will not result from policy or treaties but from the impact of changing environmental conditions due to the growth of the human economy. ... Many goods will be manufactured closer to where they are consumed, as supply chains become more regional and local." - Fred Curtis, David Ehrenfeld [8]

Scale-Up From One"Scale up from one: Regular people and small manufacturing companies that lack investment capital will be able to set up low investment, “start small and scale up as it goes” businesses. Thanks to the low-cost Internet virtual storefronts, and the low cost of small-scale manufacturing for prototypes and custom goods, new companies can get started on a shoestring budget, yet sell their wares or services to niche, global marketplaces." - Hod Lipson & Melba Kurman [9]

Sam Rose, Erik deBruijn, Suresh Fernando on basic properties of scalable open source technology projectsbasic properties of scalable open source technology projects

(distilled from discussion between Erik deBruijn, Sam Rose, Suresh Fernando) - Sam Rose (Based on discussions with Erik deBruijn and Suresh Fernando via skype early 2010 http://wagn.holocene.cc/wagn/basic_properties_of_scalable_open_source_technology_projects ) So, what can we do to prevent instability? The solution isn't to formulate vague contingency plans or return to passive optimism. Obviously, that won't work. No, the solution is to improve our resilience to these systemic shocks through a social and economic transition that follows this simple formula: Localize production. Virtualize everything else. - John Robb [10] |

- Yochai Benkler ([11], p. 22)

- Robert Theobald, The Guaranteed Income, 1966

Karim Lakhani on Communities driving Manufacturers out of the design phase"for any given company - there are more people outside the company that have smarts about a particular technology or a particular use situation then all the R&D engineers combined. So a community around a product category may have more smart people working on the product then the firm it self. So in the end manufacturers may end up doing what they are supposed to - manufacture - and the design activity might move to the edge and into the community." (http://www.futureofcommunities.com/2007/03/25/communities-driving-manufacturers-out-of-the-design-space/)

Kevin Kelly and Terry Hancock on nearly-free material production"Material industries are finding that the costs of duplication near zero, so they too will behave like digital copies. Maps just crossed that threshold. Genetics is about to. Gadgets and small appliances (like cell phones) are sliding that way. Pharmaceuticals are already there, but they don't want anyone to know. It costs nothing to make a pill." (http://www.kk.org/thetechnium/archives/2008/01/better_than_fre.php)

Steve Bosserman outlines what is most appropriate for local distributed manufacturing"strong candidates for a locally distributed manufacturing approach include ANYTHING that is agriculturally- based like food, feed, fiber, and biofuel production, much of housing and building construction including the manufacturing of inputs used in that industry, localized electric power generation using non-bio sources like wind, solar, and geothermal, and production / manufacturing of materials, components, and assemblies that use locally sourced raw materials and draw upon open-source, relatively easy to learn, appropriate technologies that can be applied in a wide range of situations-- not just a single product."

Eric von Hippel on Manufacturing around User Innovation Communities"Threadless has tapped into a fundamental economic shift, a movement away from passive consumerism. One day in the not-too-distant future citizen inventors using computer design programs and three-dimensional printers will exchange physical prototypes in much the same way Nickell and cohorts played Photoshop tennis. Eventually, Threadless-like communities could form around industries as diverse as semiconductors, auto parts, and toys. Threadless is one of the first firms to systematically mine a community for designs, but everything is moving in this direction. He foresees research labs and product-design divisions at manufacturing companies being outstripped by an "innovation commons" made up of tinkerers, hackers, and other devout customers freely sharing their ideas. The companies that win will be the ones that listen." (quotes and paraphrased by Inc. [13])

Frank Piller on User Manufacturing"User manufacturing is enabled by three main technologies: (1) Easy-to-operate design software that allows users to transfer their ideas into a design. (2) Design repositories where users upload, search, and share designs with other users. This allows a community of loosely connected users to develop a large range of applications. (3) Easy-to-access flexible manufacturing technology. New rapid manufacturing technologies ("fabbing") finally deliver the dream of translating any 3-D data files into physical products -- even in you living room. Combining this technology with recent web technologies can open a radical new way to provide custom products along the entire "long tail" of demand. User manufacturing builds on the notion that users are not just able to configure a good within the given solution space (mass customization), but also to develop such a solution space by their own and utilize it by producing custom products. As a result, customers are becoming not only co-designers, but also manufacturers, using an infrastructure provided by some specialized companies." (http://mass-customization.blogs.com/mass_customization_open_i/2007/11/webinar-the-nex.html)

Jeff Bezos on User-Manufacturing Everything"Before long, “user-generated content” won’t refer only to media, but to just about anything: user-generated jeans, user-generated sports cars, user-generated breakfast meals. This is because setting up a company that designs, makes and globally sells physical products could become almost as easy as starting a blog - and the repercussions would be earthshaking. " (http://www.usatoday.com/tech/columnist/kevinmaney/2006-11-21-amazon-user-generated-products_x.htm)

Flexible Manufacturing and the Maker Movement"Two future forces, one mostly social, one mostly technological, are intersecting to transform how goods, services, and experiences— the “stuff” of our world—will be designed, manufactured, and distributed over the next decade. An emerging do-it-yourself culture of “makers” is boldly voiding warranties to tweak, hack, and customize the products they buy. And what they can’t purchase, they build from scratch. Meanwhile, flexible manufacturing technologies on the horizon will change fabrication from massive and centralized to lightweight and ad hoc. These trends sit atop a platform of grassroots economics—new market structures developing online that embody a shift from stores and sales to communities and connections." (http://iftf.org/node/1766) |

Introductory Resources | |

Mappings and Typologies1. The integrated open design and manufacturing process, a poster by Thomas Lommee at http://www.intrastructures.net/yes_we_re_open.pdf

* In a networked society, Investment is about sharing beliefs, leading towards decentralised financing platforms. * In a networked society, Design is about sharing ideas, leading towards a common design vocabulary. * In a networked society, Production is about sharing tools and workshops, leading towards flexible, small-scale production * In a networked society, Retail is about sharing interests, leading towards a reconnection between makers and buyers. * In a networked society, Consumption is about sharing experiences, leading towards customer-driven innovation. * In a networked society, Recycling is about sharing materials, leading towards closed material cycles

Introductory Articles

|

Key Resources

Articles

Other essential articles/essays are:

Also:

BlogsA comprehensive list of Fabrication Media is kept by the Fab Wiki [26] A selection:

See also: BooksGeneral

Community and Discussion Sources

See also:

and: |

Companies

Selection from the List of Open Hardware Organizations from GOSH 2009

- Open Pattern - Embedded Systems Engineering (OSH) - Paris, France

- Make Magazine - promotes DIY and OSH culture

- Adafruit (OSH electronics) - New York USA

- Oomlout (OSH electronics) - Vancouver BC

- Liquidware (OSH electronics) - USA

- Modern Device Company (OSH electronics)- Rhode Island, USA

- Evil Mad Scientist (OSH electronics)- USA

- Traversal Technologies - U.K.

- SparkFun Electronics - Colorado USA (e.g. Lilypad, Arduino pro and PCB design libraries)

- NORTD (OSH + OSS multitouch) - New York USA and Austria EU

Conferences and Events

- The Grounding Open Source Hardware (GOSH!) Summit at The Banff Centre serves to bring together the many and disparate makers, producers, theorizers, and promoters of physical objects that come to life under open and distributed models. This Banff New Media Institute (BNMI) summit will highlight and facilitate the emerging dialogue on both artist-driven and socially conscious open source hardware projects.

Examples

See Product Hacking for our comprehensive open hardware and manufacturing directory

- Top 5 Consumer Open Source Hardware Projects, i.e. 'ready to use':

- Chumby: "The internet-alarm clock-information-station does more than just run Linux. With a 3.5” touchscreen, an ARM9, integrated Wi-Fi, and an accelerometer, all wrapped up in a rotund, friendly enclosure, there’s no question that it’s a bona fide consumer gadget."

- Bug Labs’ BUG

- The VIA OpenBook was a concept for an open source hardware netbook released in 2008. Unfortunately, while VIA has long since launched other netbooks, it seems like this was more a marketing attempt than a full-fledged project.

- Qi Hardware NanoNote: an open source hardware handheld mobile PC

- OpenMoko’s Neo FreeRunner: open source smartphone

Organizations

- Open Hardware Initiative: Lobbying Open Source Hardware

- Open Hardware Foundation

Podcasts

- Adrian Bowyer on the RepRap Project;

- Andrew Bowyer on the RepRap Project and Self-replicating Machines ;

- Alex Lindsay on Digital Craftsmen for Development ;

- Anil Gupta on Appropriate Technology for Agroinnovations;

- Brenda Dayne on Knitting as an Open Craft ;

- Carl Etnier on Neighbor to Neighbor Skill Sharing ;

- David Lee and Valerie Wilson on the the Open Source Green Vehicle Project ;

- Dave Vondle on Re-examining Design for Open-Source Hardware ;

- Elizabeth Henderson on Sharing the Harvest through Community-Supported Agriculture ;

- Janne Kyttanen on Rapid Manufacturing ;

- Johan Soderbergh on Ronja as Anonymous Communication through Free-Air-Optics ;

- Limor Fried on Why Do Open Hardware ;

- Lonny Grafman and Curt Beckmann of Appropedia on Open Source Appropriate Technology ;

- Marcin Jakubowski on Open Farm Tech ;

- Marcin Jakubowski on Transition Towns and Open Source Villages ;

- Massimo Banzi on Arduino ;

- Patricia Allen and Ronald Wright on Permaculture as Sustainable Agriculture ;

- Phil Torrone and Limor Fried on the Maker Movement ;

- Sean Moss-Pultz on Open Moko ;

- Vinay Gupta and Andrew Lamb on the Appropedia Approach ;

- Vinay Gupta on Ending Poverty With Open Hardware

See also [32]:

- OSHW 2010 Summit Panel on Open Hardware Licenses and Norms

- OSHW 2010 Summit Panel on Open Manufacturing Beyond DIY

- [[OSHW 2010 Summit Panel on Open Hardware Business Models}]]

Tools

- A working directory of hardware tools are available here.

- 100k Garages is a network of Digital Fabrication shops, where your design can be fabricated [33]

- Product Hacking: directory of Open Source Hardware projects

- 3D Filter: 3D Model Search Engine: trawl sites such as Cadyou, Google 3D warehouse, The 3D Studio and seven others for 3D models in a variety of formats as well as textures

Open Source Production Machines

Full list is updated here: [34]

- Adafruit Motor/Stepper: Full-featured motor shield that will be able to power many simple to medium-complexity projects.

- AnniRouter, an open hardware CNC router

- Callooh, A free hardware CNC router project

- Clanking Replicator Project is a bootstrap 3D printer that can make you pretty much anything that can be made from plastic

- Contraptor [35]: a DIY open source construction set for experimental personal fabrication, desktop manufacturing, prototyping and bootstrapping.

- The CubeSpawn Project, an Open Source, Flexible Manufacturing System

- Desktop CNC router - A three axis cnc machine that can be easily built using standard, home handyman level, tools.

- DIYLILCNC: CNC project

- Fabaroni is a homemade 3D printer

- Fab@Home: a project dedicated to making and using fabbers - machines that can make almost anything, right on your desktop

- Global Village Construction Set: A project to design open source versions of 50 different sustainability related machines.

- LAOS Laser, another open-source laser cutter[

- Lasersaur: Open Source Laser Cutter

- LifeTrac, a tractor from the Open Source Ecology project

- MAS863 - a simple home 3D scanner

- The micRo universal fabricator is a unique system which can be used for both additive (printing) and subtractive (milling, cutting) fabrication. It is a precise, modular tool which allows you to create complex objects out of wood, metal, plastic and more. From: Lumen Lab

- Makerbot, a project of RepRap

- MakerSlide, linear bearing system

- Mantis CNC: CNC project

- Microfactories, like oomlout's wire cutting system [36]

- Multimachine, all-purpose machine tool, an example of Multiple-Purpose Production Technology

- Open Automation Project engineers modular software and electronic components, from which it is possible to assemble an intelligent PC-based mobile robot suitable for home or office environments.

- Open 3DP

- Open Grasp, an open source simulation toolkit for grasping and dexterous manipulation

- Open Hardware Repository [37]

- Open Source CNC Milling Machine

- Open Source CNC Systems

- Open Source Integrated Circuits

- Open Source Machine - Home of The MultiMachine, an all-purpose machine tool that can be built by a semi-skilled mechanic with just common hand tools.

- Open Source Torch Table, see RepTab

- Open Source XMOS Based CNC Laser Engraver Controller

- OSMIlling , an open hardware milling machine project

- OSLOOM [38], an open source thread controlled loom

- P3P, see Open 3DP, powder-based personal 3D printer student project [39]

- Pervado: see OSMilling

- Pick and Place Project: To develop a low cost, reproducible, open-source pick and place system for automated SMT electronics assembly.

- RedBlueCNC: CNC project

- RepRap - Replicating Rapid-prototyper is a self-copying 3D printer - a self-replicating machine.

- RepTab: a CNC plasma torch table (cuts through steel), by Open Source Ecology

- Ronen Kadushin Open Design - a practical repository of physical shape algorithms

- ShapeOko, another open hardware CNC router, desktop variety

- Thingiverse [40]: This is a place to share digital designs that can be made into real, physical objects.

- Ultimaker, an open hardware 3D printer

- n-e-r-v-o-u-s.com: an open source web site under the Creative Commons Attribution-Share Alike license: in which generative design methods are used to create new forms of products with the use of rapid prototyping methods. It allows members to login, download, upload and create designs.

- open furniture: OF is an open source platform that exhanges and sells designs. The concept of this effort is to create a company that can be profitable while, at the same time, can keep its interest in the idea of sharing and exchanging. The platform is open to anyone interested in design and it functions based on a point system that facilitates users to download and fabricate products.

- SourceShop - an Open Source Platform: SourceShop is a shop of digitally fabricated designer products that can be purchased by anybody. This exchange intends to go beyond its commercial aspect by expanding knowledge towards the world of digital fabrication. The main goal of SourceShop is to share knowledge between students, participants and all interested people of digital fabrication.

Webcasts

- Neil Gershenfeld on Personal Fabrication: MIT professor Neil Gershenfeld talks about his Fab Lab -- a low-cost lab that lets people build things they need using digital and analog tools. It's a simple idea with powerful results.[41]

- Eric von Hippel on User Centered Innovation: in fact, for a long time already, users (and user communities) have been responsible for most industrial innovations!!

- Video: Open Hardware is energy smart, see Dominic Muren on the Ecological Advantages of Open Hardware Manufacturing

- Dominic Muren on the Ecosystem of Digital Manufacturing: Two part video via http://www.humblefacture.com/2010/02/digifab-ecosystem-video.html

Documentaries:

- DIY Britain: on the growing Resilience movement in the UK

- Handmade Nation: Documentary on the DIY Craft Movement emerging in the U.S. and elsewhere. trailer]

- Makers, on the do it yourself renaissance

Practical:

- Pettis. Hoeken. MakerBot.

Also:

(A to D only, ported from our Webcasts directory)

- Arwen O'Reilly on the DIY Renaissance

- Beth Kolko on the effect of Hackers and ProduSers on Creativity and Consumerism

- Bre Pettis on Creating Hackerspaces ; Bre Pettis on Rapid Prototyping

- Bruce Sterling on Industrial Products And Ubiquity ; Bruce Sterling on the Internet of Things and Spimes

- CNC Embroidering ; CNC Milling Process Videos

- Cameron Sinclair on Open Source Architecture

- Chris Anderson on the New Manufacturing

- Christine Peterson on Open Source Sensing

- Citizen Engineer

- David Rowe on Open Hardware Business Models

- Dutch FabLab Story: A Shift is a documentary on FabLab in The Netherlands, in which visitors and managers tell their story. [42]

Material on Specialized Industries

From the Industrial Cooperation Project:

- Peer Production and Industrial Cooperation in Biotechnology, Genomics and Proteomics

- Peer Production and Industrial Cooperation in Alternative Energy

- Peer Production and Industrial Cooperation in Educational Materials

- Peer Production and Industrial Cooperation in Telecommunications

See the following tags:

- Food and Water, requiring Agriculture

- Fashion

- Energy

- Transportation

The special case of the fashion industry

- Between the Seams, A Fertile Commons: An Overview of the Relationship Between Fashion and Intellectual Property. By Christine Cox and Jennifer Jenkins: explores the relationship between fashion and various U.S. intellectual property regimes, examining why fashion design generally is not protectable under copyright, design patent, trademark or trade dress.

- Ready to Share: Creativity in Fashion and Digital Culture. By David Bollier and Laurie Racine: argues that the fashion business reveals a great deal about the “cultural hydraulics” of creativity and the novel ways in which intellectual property law can foster, and not restrict, creative freedom.

Open Manufacturing Encyclopedia

Pages in category "Manufacturing"

The following 200 pages are in this category, out of 1,776 total.

(previous page) (next page)3

- 3.2 Explaining the Emergence of P2P Economics

- 3.2.B. How far can peer production be extended?

- 3D Additivist Cookbook

- 3D Bioprinting

- 3D Earth Printing Construction Technology

- 3D Fabbing

- 3D Hubs

- 3D Mud House Printing

- 3D Printables

- 3D Printed Car

- 3D Printer OS

- 3D Printers for Peace

- 3D Printers, the Third Industrial Revolution, and the Demise of Capitalism

- 3D Printing

- 3D Printing as an Agent of Socio-Political Change

- 3D Printing Community and Emerging Practices of Peer Production

- 3D Printing Files Marketplaces

- 3D Printing Industry

- 3D Printing Revolution Film

- 3D Printing Step-by-Step

- 3D Printing, Intellectual Property, and the Fight Over the Next Great Disruptive Technology

- 3D Printing, the Arts and Crafts Movement and the Democratization of Art

- 3D Robotics

- 3D Scanner

- 3D Scanning

- 3D Solar Sinter Prints on Sand

- 3Drag

- 3DSUG

- 3Ducation Project

A

- Aaron Makaruk on the Open Source Ecology Project

- Aaron Makaruk, Yoonseo Kang et al. on the Open Tech Forever Project

- Ability Mate

- Access to Tools

- Adafruit

- Adafruit Industries

- Additer

- Additive Fabrication

- Additive Manufacturing

- Additive Manufacturing as Global Remanufacturing of Politics

- Additivism

- Adrian Bowyer on 3D Printers

- Adrian Bowyer on Personal Manufacturing

- Adrian Bowyer on Rapid Prototyping

- Adrian Bowyer on the RepRap

- Adrian Bowyer on the RepRap Project

- Adrian Bowyer on the RepRap Project Lab

- Advanced Automation

- Advanced Civilization

- African Fabbers

- Agata Jaworska on the Design for Download Project

- Agoblogoshie Makerspace Platform

- Agua Clara

- AI Supply Chain Observatory

- Air Data Instrument

- Alastair Parvin on the Wikihouse Open Source Construction Set

- Alastair Parvin on Wikihouse

- Alastair Parvin on Wikihouse's Open Source Architecture

- Alchematter

- Alessandro Ranellucci

- Alex Lindsay on Digital Craftsmen for Development

- Algedonics

- Alice Taylor on Personal Manufacturing

- Alicia Gibb

- Alicia Gibb and Ayah Bdeir Explain the Open Source Hardware Revolution

- Alicia Gibb on the Status of the Open Source Hardware Movement in 2012

- ALL Power Labs

- Amine Ghrabi

- Analysis of Open Hardware Licensing

- Andrew Bowyer on the RepRap Project

- Andrew Bowyer on the RepRap Project and Self-replicating Machines

- Andrew Katz on Copyleft Licensing for Hardware

- Andrew Lamb

- Andrew Lamb on Massive Small Manufacturing for Humanitarian Aid

- Anil Gupta on Appropriate Technology for Agroinnovations

- Anna Greenspan

- Anna Seravalli

- Another Production is Possible

- Anticipated Environmental Sustainability of Personal Fabrication

- Apertus Association

- Apollo

- Apollo Open Vehicle Certificate Platform

- Appropedia

- Appropedia Foundation

- Arab Hackerspaces

- Architecture Design Sharing

- Arduino

- Arduino - Business Model

- Arduino and Open Source Design

- Arduino's Open Source Hardware Business Model

- ArduPilot

- ArduSat

- Aria

- ARIA

- ArkFab Innovation Foundation

- ASAP Island

- At-Home Manufacture of Circuit Boards

- Atadiat

- Atelier Paysan

- Ateliers Fab Lab at ENSCI

- AtFab

- Atomic Duck

- Audio Files from the Open Hardware Summit 2010

- Aurélie Ghalim

- Automake

- Automated Infrastructure

- Automation and the Future of Work

- Automation, Accelerating Technology and the Economy of the Future

- Autonomous Roadless Intelligent Array

- Avi Reichental on What’s Next in 3D Printing

- Avoccado

- Ayah Bdeir

- Ayah Bdeir on littleBits

B

- Babilim Light Industries

- Backyard Biology

- Barcelona 5.0 Plan

- Barcelona MADE Project

- Barcelona Maker Faire

- Barriers and Challenges to Personal Manufacturing

- Bath Open INstrumentation Group

- Bay Area DIY communities

- BeagleBoard

- Behrokh Khoshnevis on Automated Construction through Contour Crafting

- Belt and Road Initiative

- Ben Armstrong

- Ben Einstein on Building a Hardware Company

- Bengt Sjölén

- Best of Instructables

- Best Practices of Open Source Mechanical Hardware

- Better Be Running

- Bibliography on Localizing and Distributing Production

- Bibliography on Open Design and Distributed Manufacturing

- Big Blue Saw

- Bike Kitchen

- Bike Kitchens

- Bio and Hardware Hacking

- Biohackers

- Biohacking

- Biohacking Safari

- BioPunk

- Bioregional Fibershed

- Biospace - Canada

- Bit Beam

- Bits From Bytes

- Blade

- BoardForge

- Bob Haugen

- BotQueue

- Bottega21

- Bram Geenen

- Brazilian Hackerspaces as Spaces of Resistance and Free Education

- Bre Pettis on Creating Hackerspaces

- Bre Pettis on Rapid Prototyping

- Bre Pettis on the History of MakerBot

- Bre Pettis on the Open Source Making Methodology

- Brenda Dayne on Knitting as an Open Craft

- Bret Victor on Design Tools for Makerspaces as Communal Spaces

- Bricolabs

- Bricoleur

- Brief History of Open Source Hardware Organizations and Definitions

- Brmlab

- Bronac Ferran, and Andrew Prescott on Contemporary Making as a New Way of Thinking

- Bruce Sterling on Industrial Products And Ubiquity

- Bruce Sterling's Update on "Shaping Things"

- BUG

- Bug Labs

- Build It Solar

- Building an Economy of the Commons Through Open Distributed Manufacturing Structures

- Building Blocks

- Building Open Source Hardware

- Bunnie Huang

- Business Models for DIY Craft

- Business Models for Fab Labs

- Business Models for Open Hardware

- Business Models of Fab Labs

C

- C,mm,n

- C3POW

- CAD for Personal Manufacturing

- Camera Libre

- Cameron Sinclair on Open Source Architecture

- Can 3D Printing Lead to Mass Manufacturing

- Can Peer Production Make Washing Machines?

- CandyFab Project

- Carl Etnier on Neighbor to Neighbor Skill Sharing

- Carolina Rossini on the Industrial Cooperation Project

- Carsharing

- Casa Jasmina

- Case for Open Source Appropriate Technology

- Case of a RepRap-Based, Lego-Built 3D Printing-Milling Machine

- Catarina Mota

- Catarina Mota on Open Materials

- Catarina Mota on the Open Materials Movement

- CCCKC 2011 Panel on Maker Movement, 3D Printing, and Fabrication

- Center for Community Production

- CEO Guide To Making Prototypes for 3D Printing

- CERN Open Hardware License