Distributed Manufacturing

Description

From the Wikipedia:

"Distributed manufacturing also known as distributed production, cloud producing and local manufacturing is a form of decentralized manufacturing practiced by enterprises using a network of geographically dispersed manufacturing facilities that are coordinated using information technology. It can also refer to local manufacture via the historic cottage industry model, or manufacturing that takes place in the homes of consumers." (https://en.wikipedia.org/wiki/Distributed_manufacturing)

Impact

Orestes Chouchoulas:

"A distributed manufacturing network supported by this metadata layer could have a transformative impact in several significant ways:

Material and energy efficiencies

On-demand production already carries the potential of dramatically reducing resource waste by removing the need to predict demand. The metadata layer could take these efficiencies further by allowing infinitely granular quality assurance. Take plywood as an example: beyond grading for the physical appearance of the facing plies, batches of plywood sheets undergo multiple tests (e.g. boiling, pressure, and shear tests) and inspections at the point of manufacture. Sheets that are within acceptable performance tolerances are marked as compliant and sheets that fail the tests are often discarded or recycled; a binary mark of quality. A metadata infrastructure would instead offer the option of marking all sheets with their particular levels of performance, to be selected as needed for particular uses.

What else could be possible given this sort of digital quality assurance infrastructure? Could the output product be verified automatically as a consequence of metadata-aware tooling and processes?

Parametrisation of design

Linking materials and component parts to particular specification metadata also unlocks outcome based design processes using parametric design software. Products designs will no longer need to address model use cases, but instead can be automatically customised to generate the necessary performance for the outcomes at hand. If a larger desk is needed, parametric design software will specify either more robust materials, or additional bracing to prevent excessive sagging. The metadata structure encodes the certified limits of each customised design, and therefore the conditions of their warranties. What would this mean for products that need to be customised by definition, like prosthetics? What would it mean for the apparel industry to have the potential to custom tailor any piece of clothing at the cost of ready-to-wear garments? And what are the possibilities for mass-produced items that have never been able to be customised for particular uses?

From retail to service business models

Being able to specify custom products for specific outcomes foreshadows a move from business models that sell predetermined products to outcome-based service contracts: from selling desks to enhancing workspace productivity for a growing company, for example. As the needs of the end user change, the service provider can adapt or replace products to suit, creating a long-term service relationship with the clients, and innovating their physical offerings in partnership. Insurance and warranties for newly conceived products can happen automatically as an operation on the metadata. But what could this mean about the future of product ownership? Could this also be heralding a move away from retail transactions for the transference of ownership to a new kind of DRM — the digital management of rights to materials, components, and products? And could the financing of products become contingent on digital warranties?

Continuous hackability and distributed innovation

With specifications of all parts of a product available on demand and automated certification, every product can become adaptable, reusable, and continuously hackable, without voiding warranties or losing consumer protection rights. In essence, this creates a massive distributed innovation engine for the improvement and repurposing of products. Coupled with open source licenses (that can also be embedded in metadata) the benefits of adaptations and improvements can be shared globally.

What implications would this have on the discipline of product design? How could this change design education, business models, and IP protection practices?

Democratisation of supply chains

When product design and fabrication becomes this responsive to specific local needs, supply chains can be structured around value creation at the point of use.

Adding the metadata infrastructure allows every user to become a designer and a maker with the same level of technical, legal, and institutional support that so far only large industrial concerns can afford.

What new business models could this enable? What new regulation models would they require? How could the right balance between innovation and regulation be achieved?

The introduction of a standardised data layer should happen across both open making and traditional manufacturing processes, enabling grafting, tweaking, customisation, and repair, without negating existing business models." (https://provocations.darkmatterlabs.org/the-grey-matter-of-supply-chains-bab2865fa314)

Timeline Discussion

Initial Thesis

John Robb:

"“John Robb:

“Already, the fabrication equipment necessary to build complex objects/products costs only $20-50 thousand (some systems are in the hundred dollar range) and the costs are plunging. Given the technological trends, it will be possible in the next decade or so to produce nearly any product locally through these local fabricators in a cost competitive way — some at home and the rest at a local shop." (http://globalguerrillas.typepad.com/globalguerrillas/2008/09/resilient-com-1.html)

Reactions

Bryan Bishop [1]:

"3D printing is just molds at the moment, correct. The timeline might not be too absurd. I think it's all possible *right now* given critical mass support and contributors."

Vinay Gupta [2]:

"distributed manufacturing... **of what?** is the critical question.

mass manufacture is always going to be cheaper for things which are pretty much the same and have no need of variation - plastic buckets, paper, tires. There's just no way, until you assume extremely sophisticated ultratechnology, that you can do that kind of stuff price competitively with mass manufacture.

stuff where a combination of supply chain logistics, customization, irregular demand and other factors makes mass manufacture implausible is already being done using distributed manufacturing. the biggest example of that, which nobody talks about, is housing which is all done with entirely redundantly stupid distributed manufacturing resulting in absurdly high prices for items which should come off production lines for 10% of the cost of hand-assembled individually unique boutique housing, which is currently the only model generally available.

Giant housing factories, trust me on this, giant housing factories.

The real sweet spot for distributed manufacture is stuff that people currently *aren't* making because it's impossible. The perfect pair of shoes, clothes you helped design, portable electronics and computers that do it your way, car seats designed to your personal ass, beds which fit perfectly in the space you have and are just as hard/soft as you like them, and so on. It's not about direct replacement of stock with custom, it's about custom and new in places where mass manufacturing is failing.

Any place you see 5000 functionally equivalent items in a store, and you go in and sort through for what you need, you have a distributed manufacturing opportunity. Off the top of my head:

- book shops

- shoe shops

- hardware stores

- posters / art

- clothes

Note that a lot of this stuff, in reality, would be feedstock supply chain bound. Ink and paper stream to the book printer at the local university book shop. Metal to the hardware store and so on. Going the whole hog, and doing resource extraction etc. on the spot is absolutely going to happen but mainly in rural areas for a class of products suited to that lifestyle niche.

Exceptions to that: places where the supply chain is a loop, where people drop off their items to be locally broken down and made into something else, on demand.

To me, distributed manufacturing is not about providing the current good and services for the most part, but about building what people actually want and need, once the gap between economies of scale and individual design is closed far enough that people will pay the premium for getting exactly what they want, here and now, rather than dealing with the remote factory."

Smary McCarthy [3]:

"As much as I like the idea of 3D printing and the digital fabrication revolution and all that, as much as I am a strong proponent of it, I just really can't see anybody with the right know-how addressing the real issues involved, which are that what we have today is just too high tech and complicated and useless to be deployed in the field.

So, before this timeline becomes realistic in any way, we need to figure out how to digitize and distribute the basic transformative processes such as, well. I'll be happy when I can fabricate everything in the room you're in, including the room itself, in my lab.

Once this is realistic, we can start talking about a timeline. Until then, nobody - not the MIT people, not the Fab Lab people, not the economics people trying to figure out how this will change everything, not anybody - is doing anything remotely as important as Marcin and the OSE crew, who are effectively scaling down /analogue fabrication/ and pushing it into a more sustainable pathway."

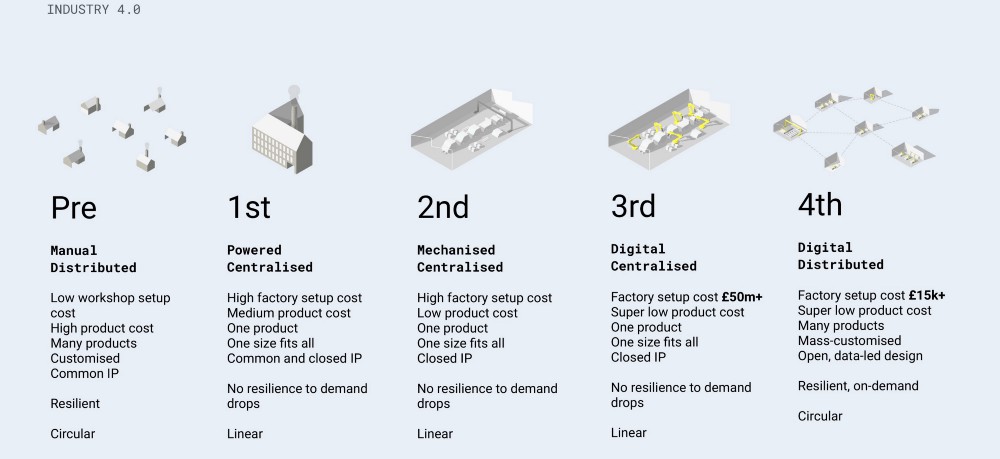

Visualizations

From: https://provocations.darkmatterlabs.org/democratic-making-c5ada37db594

More information

* Article: Distributed manufacturing: scope, challenges and opportunities. By J. Srai, Mukesh Kumar, A. Tiwari et al. International Journal of Production Research, 16 June 2016

"A discussion on the changing nature of manufacturing as a result of DM."

Abstract:

"This discussion paper aims to set out the key challenges and opportunities emerging from distributed manufacturing (DM). We begin by describing the concept, available definitions and consider its evolution where recent production technology developments (such as additive and continuous production process technologies), digitisation together with infrastructural developments (in terms of IoT and big data) provide new opportunities. To further explore the evolving nature of DM, the authors, each of whom are involved in specific applications of DM research, examine through an expert panel workshop environment emerging DM applications involving new production and supporting infrastructural technologies. This paper presents these generalisable findings on DM challenges and opportunities in terms of products, enabling production technologies and the impact on the wider production and industrial system. Industry structure and location of activities are examined in terms of the democratising impact on participating network actors. The paper concludes with a discussion on the changing nature of manufacturing as a result of DM, from the traditional centralised, large-scale, long lead-time forecast-driven production operations to a new DM paradigm where manufacturing is a decentralised, autonomous near end user-driven activity. A forward research agenda is proposed that considers the impact of DM on the industrial and urban landscape."